Our business unit microComponents offers you a wide range of microfluidic components. Bartels Mikrotechnik produces and distributes microfluidic products – especially for miniaturized and portable applications.

The products are cost-efficient, take up minimal space and are very user-friendly. This makes fluid management a breeze.

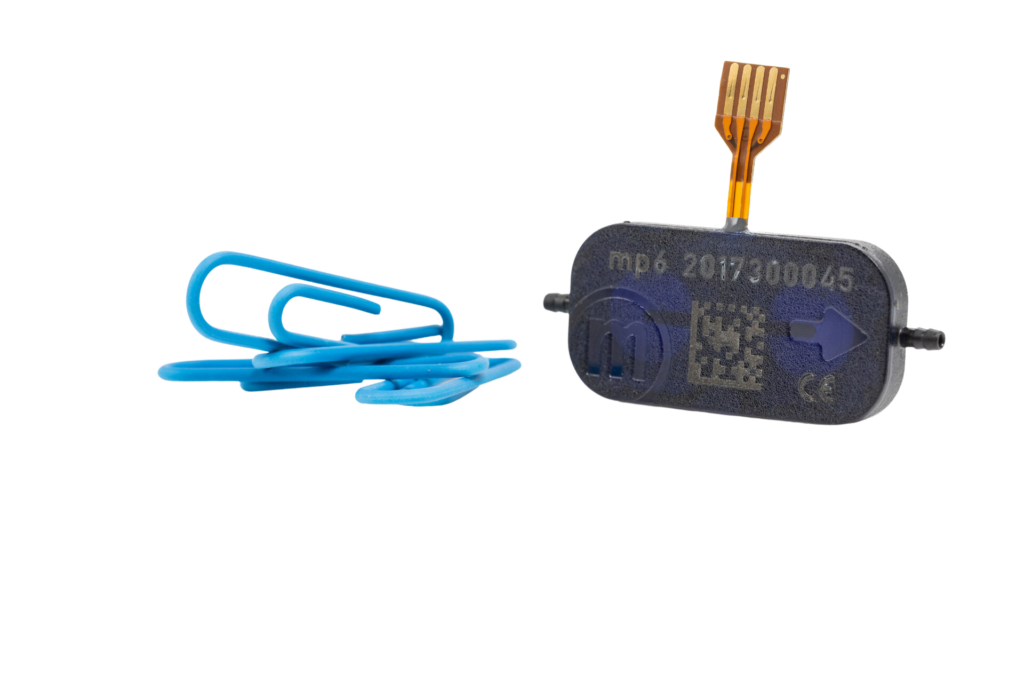

Our key products are micropumps that pump small quantities of gases and liquids. They are used in a variety of applications in biotechnology, pharmaceuticals and medical technology.

We offer you first-class R&D services for individual research and development projects.

Our expertise in microfluidics, micropump integration, electrical engineering and software development enables customized solutions for your requirements.

Depending on your requirements, we also offer in-house testing and R&D kits with components & hourly quota.

Some of our partners are GENSPEED Biotech GmbH, Kühner AG and AICUBE, we always go beyond traditional business boundaries to create innovative solutions.

Together with GenSpeed Biotech, we are setting new standards in molecular biology. Our technologies are merging to enable breakthrough advances in gene analysis. The combination of our expertise opens pathways to more precise results and accelerated discoveries.

Our collaboration with Kühner AG paves the way for environmentally friendly innovations. Together, we are developing advanced bioreactors that offer the highest efficiency and sustainability. This partnership is helping to reshape the bioprocessing industry.

With AICUBE, we work at the forefront of Artificial Intelligence and Data Analytics. Our synergy enables data to be transformed into valuable insights. This partnership drives the development of intelligent systems that optimize decision-making processes and shape the future.

In collaboration with these renowned companies, we are boldly breaking new ground. Our common goal is to push the boundaries of what is possible and drive innovation that has a positive impact on industry and society.

For more than 25 years now, we have been a globally active manufacturer and development service provider in the field of microfluidics. Together with our partners, we help our customers find the right microfluidic solution for their application.

As microfluidic SolutionMaker, Bartels offers a complete, application-oriented and modular liquid handling system. With our evaluation sets you can test our mp6 micro pump directly in your application. We have already prepared everything for you.

Please have a look at our new product line here:

Do you have any questions about one of our products or services?

Call the telephone number shown, or click on the number to call us directly.