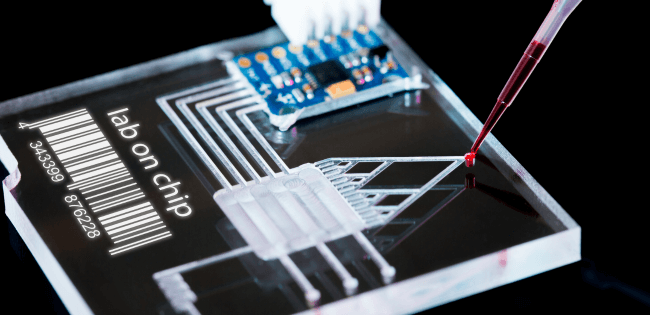

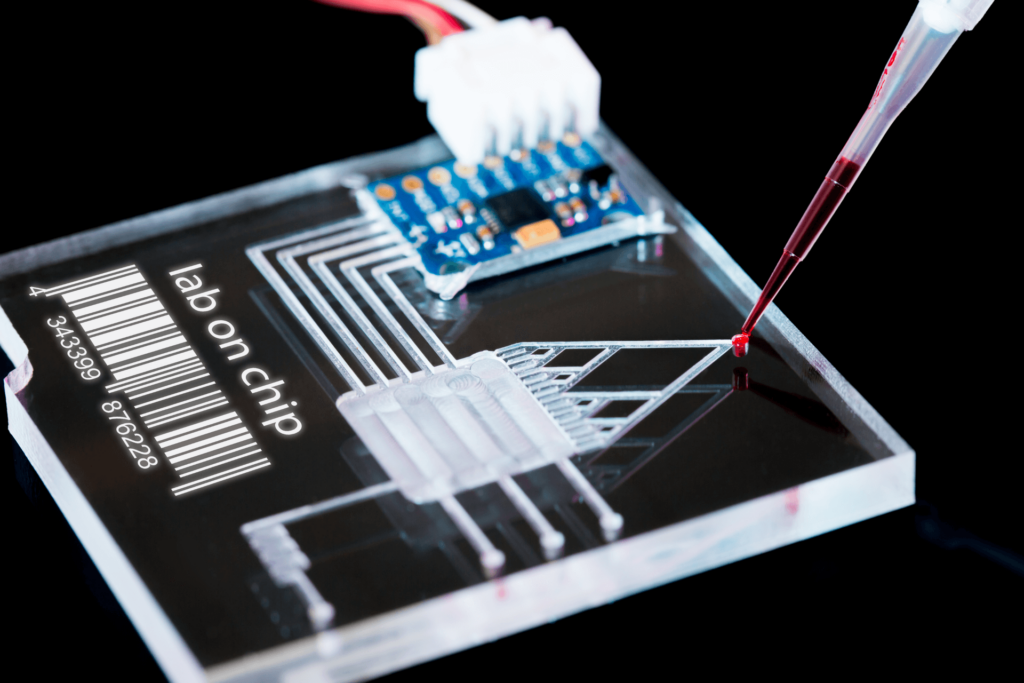

Aufbau eines Lab-on-a-chip-Systems

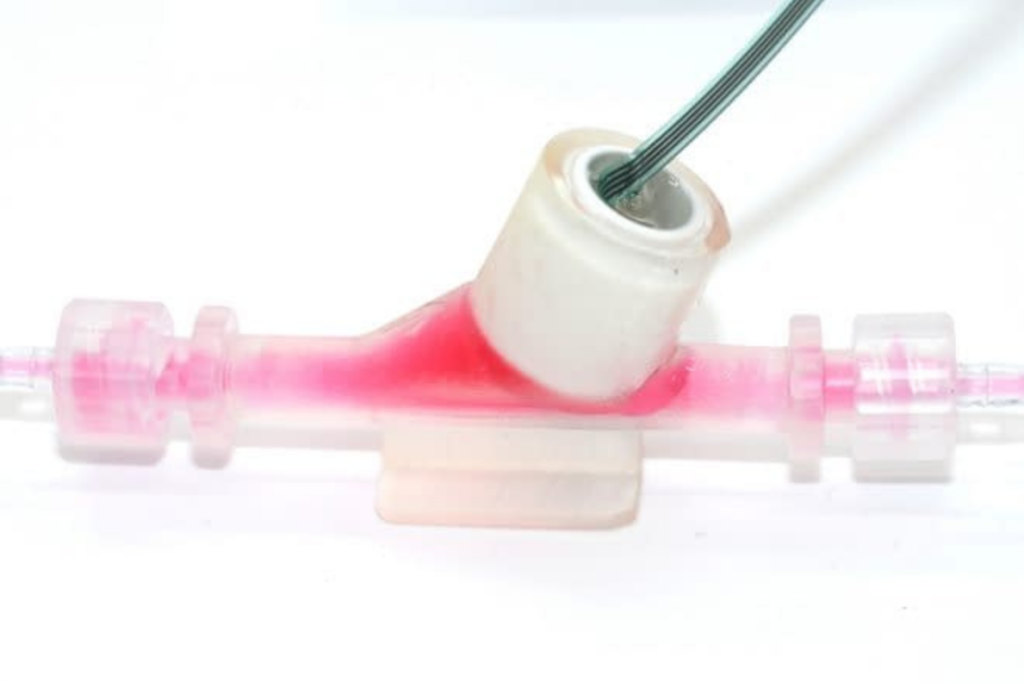

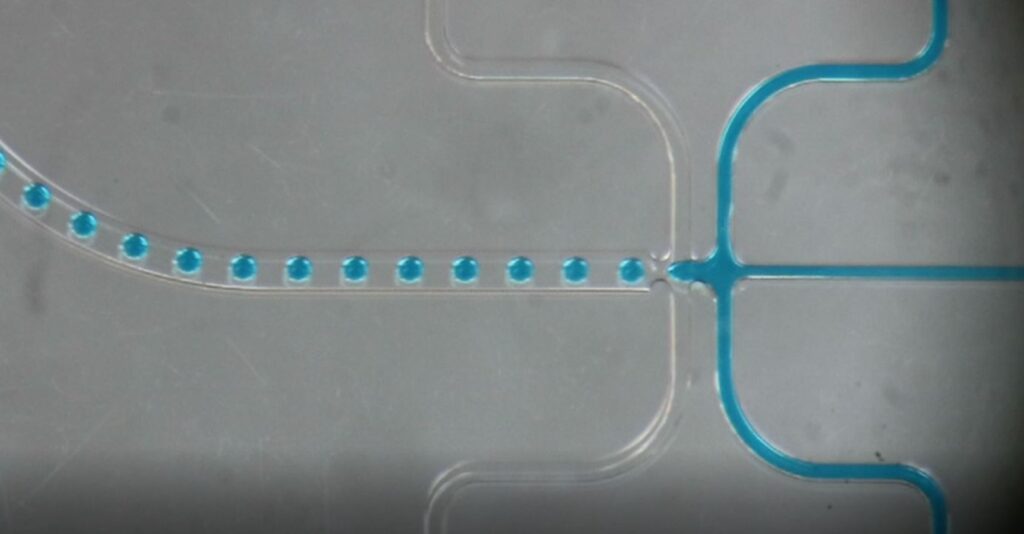

Unsere mp6 Mikropumpe erweitert passive Mikrofluidik-Chips und wandelt sie in aktive Einheiten um. In der Mikrofluidik sind wir fast immer laminaren Strömungen ausgesetzt. Dies führt zu einem Mangel an Querströmung innerhalb der Flüssigkeit und macht es schwierig, zwei Flüssigkeiten zu mischen.

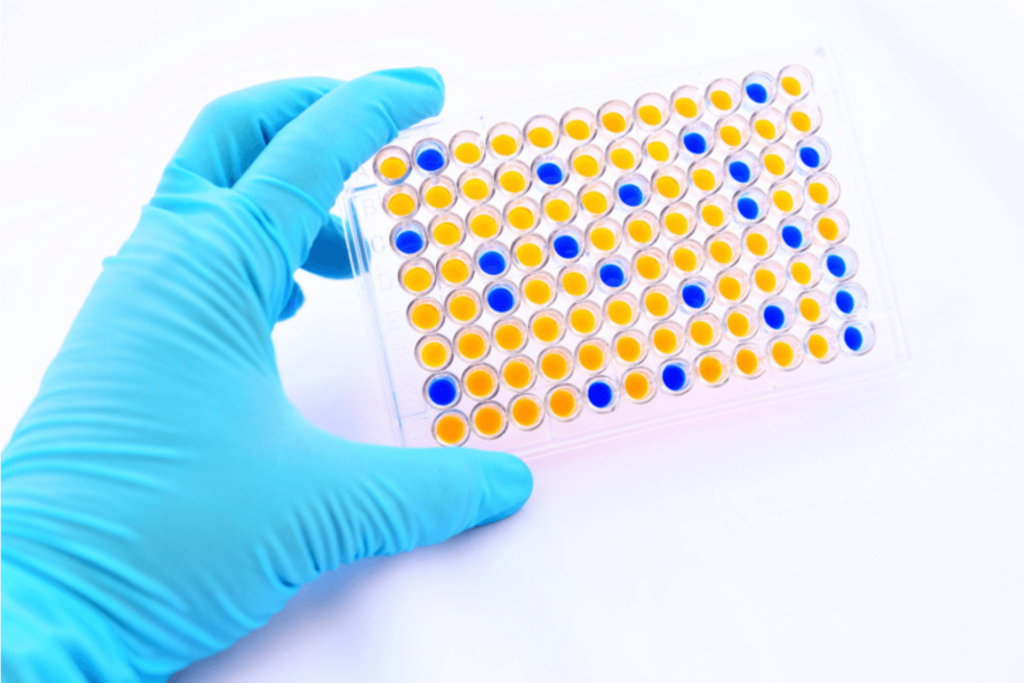

In diesem Video wird diese Querströmung durch eine spezielle Struktur des mikrofluidischen Chips hervorgerufen. Dadurch lassen sich die beiden unterschiedlich gefärbten Flüssigkeiten leichter mischen. Die Mikropumpe wird elektronisch angetrieben. Sie ermöglicht diesem schlanken, kleinen und preiswerten System das schnelle und sichere Befüllen selbst kleinster und komplexer Strukturen. Dies ist zum Beispiel die Basis für Lab-on-a-Chip-Anwendungen.

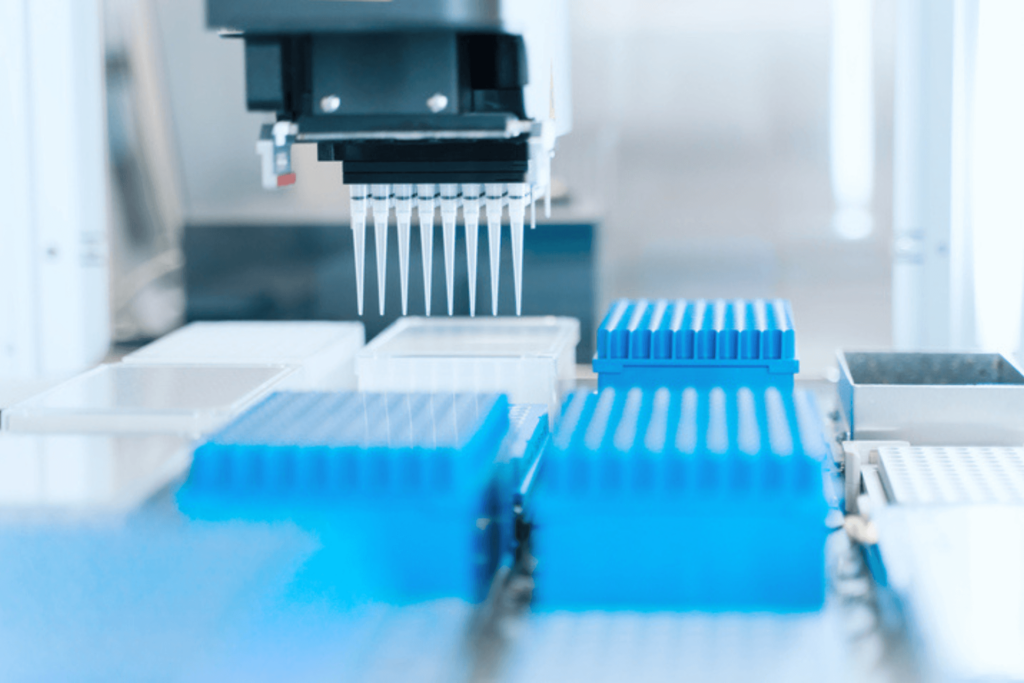

Statt mit herkömmlicher Labortechnik können Tests und Diagnosen direkt am Point of Care durchgeführt werden. Das spart Zeit und Kosten und führt zu einer höheren Funktionalität des Systems. Das flache System kann in tragbare Geräte integriert werden, die digitale Handhabung ermöglicht eine variable Flussrate und eine einfache Bedienung.

Mit dem Laden des Videos akzeptieren Sie die Datenschutzerklärung von YouTube.

Mehr erfahren